|

I come from a long line of boat builders, Heislers, Stevens and Levys. My great-grandfather

(my paternal grandmother's father) was none other than the famous wooden schooner builder Reuben

Heisler, who built at least 35 Tancook Schooners in the early 1900's. One of his schooners

(ADARE 40 ft, 1906) was in the last "Tall Ship" Parade of Sail (2000). My great-great-uncle

Wesley Stevens (my paternal grandmother's, mother's brother), built his last sailboat when

he was well into his 80's.

My Dad also worked for a time for Grandpop Heisler (Reuben) in his boat shop in Chester's

back harbour. So it was only a matter of time before I built my first double-ended boat.

I come from a long line of boat builders, Heislers, Stevens and Levys. My great-grandfather

(my paternal grandmother's father) was none other than the famous wooden schooner builder Reuben

Heisler, who built at least 35 Tancook Schooners in the early 1900's. One of his schooners

(ADARE 40 ft, 1906) was in the last "Tall Ship" Parade of Sail (2000). My great-great-uncle

Wesley Stevens (my paternal grandmother's, mother's brother), built his last sailboat when

he was well into his 80's.

My Dad also worked for a time for Grandpop Heisler (Reuben) in his boat shop in Chester's

back harbour. So it was only a matter of time before I built my first double-ended boat.

I built models as a kid, and made a planked wooden replica of Dad's 1945, 30 foot Cape Islander

called the "Hubba Hubba II" in my 20's. Cecil Levy and my Dad built two cape boats the winter

of '45.

I built models as a kid, and made a planked wooden replica of Dad's 1945, 30 foot Cape Islander

called the "Hubba Hubba II" in my 20's. Cecil Levy and my Dad built two cape boats the winter

of '45.

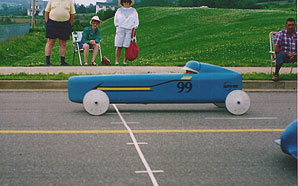

In 1991, my son and I built a Soap Box racer using the stripper style, with a closed, cigar-like

shape. Our racer was undefeated in its first season, and under my daughter's piloting, in its

third season, won the trophy for overall fastest Soap Box racer in the Bearing class (1993).

It didn't float, but we were getting closer.

Since around 1974 when I bought my first canoe, (14 ft cedar/canvas) I started to appreciate

the canoe and knew I would build one some day. Usually when I see something I'd like to have,

I don't say, "how can I get the money to buy it", but "how can I make one".

Since around 1974 when I bought my first canoe, (14 ft cedar/canvas) I started to appreciate

the canoe and knew I would build one some day. Usually when I see something I'd like to have,

I don't say, "how can I get the money to buy it", but "how can I make one".

Building a canoe took a little longer to happen than some of my ideas, but along the way I

helped a friend, David McRae, with two of his Cedar strippers, and re-canvassed my 14 footer.

During a church fall retreat at Camp Mush-Mush in 2001, we looked up in the log rafters of

the Dining Hall at an unfinished cedar strip canoe, which had been stored there. My friend

Stephen Rand asked, "Can we make one of those?" Those that know me would know the answer

(as Stephen did before he asked)."Yes!" was my reply and the "Plan" started. We would build

two, Stephen's first, then mine.

As we prepared to start, another friend of ours, David McCurdy got wind of the "Plan" and

then there were three canoes to build. Stephen had a connection to New Brunswick white cedar,

and before you could say "cedar strip", there were two live-cut cedar logs in Stephen's

driveway. We had them milled into 1" thick boards, then air-dried them in Stephen's Dad's

basement. David had the woodworking gear, so we cut the strips and did the bead-and-cove

edging at his place.

As we prepared to start, another friend of ours, David McCurdy got wind of the "Plan" and

then there were three canoes to build. Stephen had a connection to New Brunswick white cedar,

and before you could say "cedar strip", there were two live-cut cedar logs in Stephen's

driveway. We had them milled into 1" thick boards, then air-dried them in Stephen's Dad's

basement. David had the woodworking gear, so we cut the strips and did the bead-and-cove

edging at his place.

Stephen chose to build a 16' Chestnut Prospector, from Canoecraft by Ted Moores and Merilyn

Mohr. The construction went well and we experimented and learned as we built, modifying

and inventing new methods to suit us. We completed his canoe in the fall of 2002, just in

time to take it to the Church fall retreat at Camp Mush-a-Mush, the birth place of the "Plan",

for its maiden voyage.

As we were building the first canoe, I was trying to decide what to build. Since I already

had 5 or 6 canoes, the choice was somewhat difficult. I've wanted my own stock boat for a while,

so it seemed like the best choice, but there didn't seem to be any design available. So by

using the Canoecraft section on "Designing Your Own", a Gillies 18-ft stock boat, and pictures

and measurements of a Wenonah 18' Jensen, I came up with the design for the "Levy Cruiser".

By the end of Nov. 2002, we had enough strips made for the next two canoes and my stations

set up on the strong back. We used white cedar for the majority of the planking strips, trying

to use mostly the richer-coloured ones. For the two accent strips, I recycled some window

framing from my Church's latest renovations, at least 39 year-old redwood.

By the end of Nov. 2002, we had enough strips made for the next two canoes and my stations

set up on the strong back. We used white cedar for the majority of the planking strips, trying

to use mostly the richer-coloured ones. For the two accent strips, I recycled some window

framing from my Church's latest renovations, at least 39 year-old redwood.

One of my goals was to try to keep weight down, so I only used inside stems and inside gunwales.

The stems were made of three pieces of white ash, steamed and laminated. I used laminated

ash and redwood 1/2" by 3/4" (finished size) for inside gunwales, and I turned on my lathe

a piece of laminated stock for carrying handles. We used fibreglass cloth and the East System

Epoxy resin inside and out, with marine spar varnish and UV protection, for the finish.

Lightweight aluminum was used for seat supports and thwarts.

The process of building a strip canoe is well laid out in Canoecraft . We totalled about

250 working hours in building the "Levy Cruiser", working for the most part every Monday

evening for 3-4 hours planking, planing and sanding. When it came to fibreglassing and

finish work, Saturdays and any free time was used to get the canoe ready for the 2003 Annapolis

River race on May 10. The canoe came off the assembly line at 2:00 am the morning of the race!

The project was definitely a positive one, attracting many visitors to Stephen's garage,

checking out our progress, helping to add a plank, sanding, laying out fibreglass cloth,

mixing or rolling on resin, or attaching final hardware. The "Levy Cruiser" tipped the scales

at 49 lbs and took first place in her first race. She competed again in the PPP relay in

September, performing up to expectations. The canoe handles very well, with good stability.

My wife and I have paddled it a fair amount this past summer and it is an easy-paddling, stable,

touring canoe.

The process of building a strip canoe is well laid out in Canoecraft . We totalled about

250 working hours in building the "Levy Cruiser", working for the most part every Monday

evening for 3-4 hours planking, planing and sanding. When it came to fibreglassing and

finish work, Saturdays and any free time was used to get the canoe ready for the 2003 Annapolis

River race on May 10. The canoe came off the assembly line at 2:00 am the morning of the race!

The project was definitely a positive one, attracting many visitors to Stephen's garage,

checking out our progress, helping to add a plank, sanding, laying out fibreglass cloth,

mixing or rolling on resin, or attaching final hardware. The "Levy Cruiser" tipped the scales

at 49 lbs and took first place in her first race. She competed again in the PPP relay in

September, performing up to expectations. The canoe handles very well, with good stability.

My wife and I have paddled it a fair amount this past summer and it is an easy-paddling, stable,

touring canoe.

Bernie Levy

|